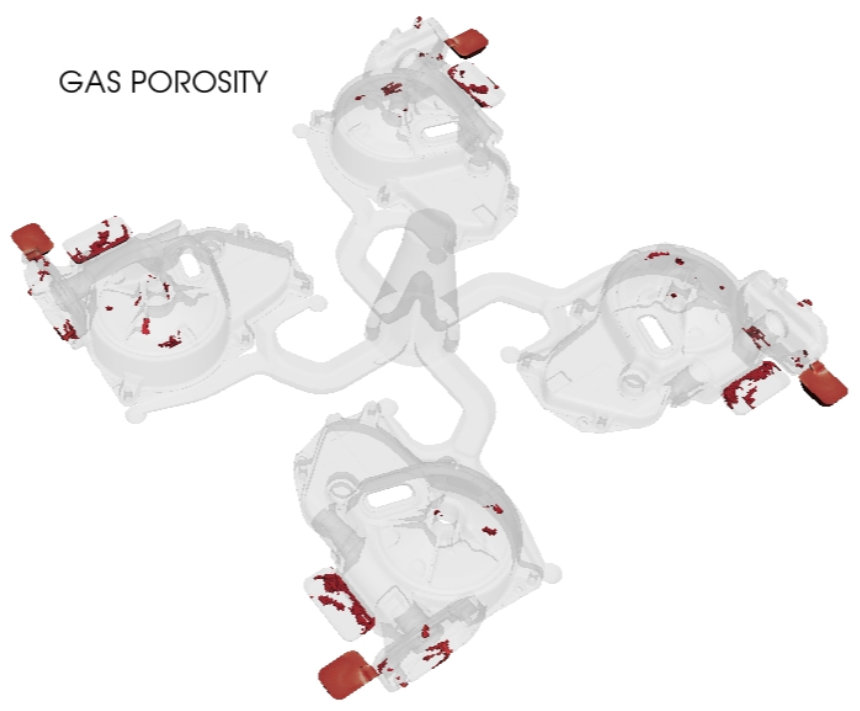

Unlike the aluminum alloys, the main problems with die casting magnesium alloys are not related to solder. Since magnesium alloys solidify much more rapidly, proper filling of the die cavity and prevention of cold flow defects are the primary concern of the die caster. Castle is the right tool for simulating Mg die casting: at high speed rate the metal doesn’t present a united flow front but it is crushed in many minute droplets which are composed of both metal and air. In Castle the single mesh cell is filled up by a mixture of both metal and air by increasing significantly the accuracy level of gas porosity prediction.

Unlike the aluminum alloys, the main problems with die casting magnesium alloys are not related to solder. Since magnesium alloys solidify much more rapidly, proper filling of the die cavity and prevention of cold flow defects are the primary concern of the die caster. Castle is the right tool for simulating Mg die casting: at high speed rate the metal doesn’t present a united flow front but it is crushed in many minute droplets which are composed of both metal and air. In Castle the single mesh cell is filled up by a mixture of both metal and air by increasing significantly the accuracy level of gas porosity prediction.

Since magnesium solidifies much faster than other alloys it is very important to consider the rheology of the metal. Castle calculates the change of viscosity and the metal solidification also during the filling phase in a very limited temperature range. It makes the results much more accurate in terms of possible issues detection (i.e. cold slugs or incomplete filling) and temperature distribution visualization.

Features

- Full 3D CAD capabilities

- Model preparation and setup for the calculation in under a few minutes

- Multiprocessing and cloud computing compatible

- Dual Phase simulation: metal pulverization, spray effect and micro air entrapments detected

- Vacuum and vent effects calculation

- Interactive practical suggestions